Respiratory Protection Program

When an employer requires respirator use by its employees, the Occupational Safety and Health Administration (OSHA) Respiratory Protection standard requires all employees to follow a comprehensive and effective respiratory protection program. The program must be in writing, have a designated administrator, and specify the employer’s policies and procedures for the use of respiratory protection in the facility. OSHA requires each respiratory protection program to include several specific elements, but leaves the specifics of the policies and procedures used to meet these requirements up to individual employers.

Respiratory protection programs in healthcare

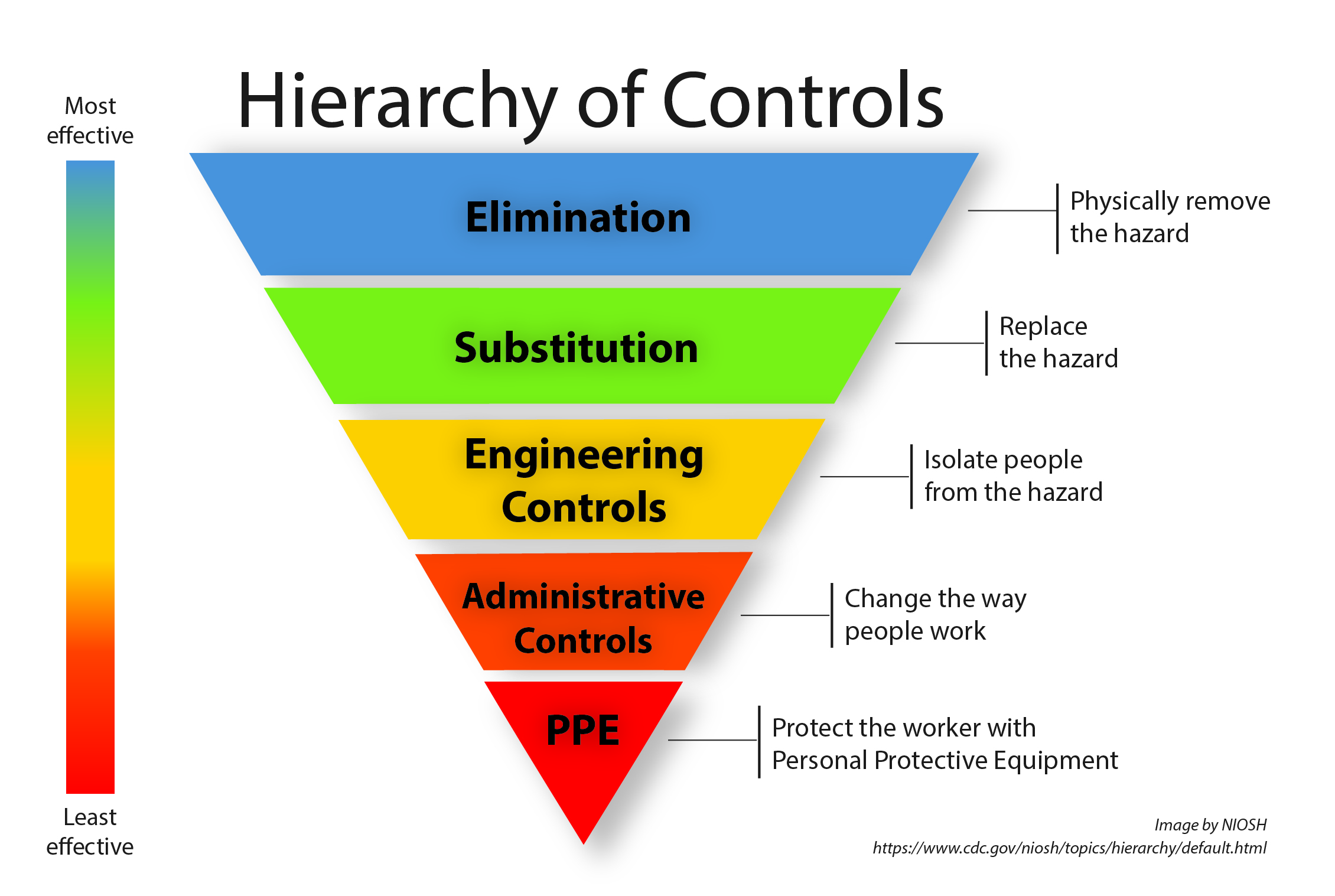

The healthcare environment contains hazards such as bacteria, viruses, and chemicals that may be inhaled by personnel and cause injury or illness. OSHA and CDPHE chapter 2 general licensure standards require health care facilities to use a “hierarchy of controls” to reduce exposure.

This means starting with the most effective controls: The elimination of hazards from the workplace, or substitution of less hazardous processes, chemicals, or products. Next in the hierarchy are engineering controls, which involve modifying equipment and/or other physical aspects of the workplace to reduce or prevent worker contact with the hazard, by isolating the hazard and/or using specialized ventilation (e.g., isolation rooms or laboratory hoods). Where these controls are not feasible or adequate, administrative controls (e.g., providing vaccinations or triaging patients) and work practices (e.g., following respiratory hygiene/cough etiquette strategies or keeping chemical containers capped) are used to reduce risk, most often by minimizing the extent or duration of the exposure, or by reducing the number of employees exposed. Respirators and other personal protective equipment (PPE) are used as a last line of defense when exposures cannot be reduced to an acceptable level using these other methods. The best occupational health practices to protect workers involves using a layered approach of techniques that fall across different tiers of the Hierarchy of Controls.

Does your entity require a Respiratory Protection Program?

Key elements needed for the successful development of a Respiratory Protection Program

- Assign roles and responsibilities- The people responsible for the development, implementation, and maintenance of the program should be identified and appropriately trained.

- Hazard analysis.

- Identify types of exposure, people who are exposed, activities necessitating exposure, and local/state/federal guidance on additional risks.

- Do this for all identified respiratory hazards. This allows the administration to identify minimum level protection required for all identified hazards.

Components of a Respiratory Protection Plan

- An OSHA-compliant written respiratory protection program includes the following essential components:

- The nine OSHA provisions:

- Risk assessment respirator selection.

- Medical evaluation.

- Fit testing.

- Procedures for day-to-day use vs. emergency use.

- Respirator maintenance.

- Suitability procedures.

- Respiratory hazards and exposure training.

- Appropriate respirator use.

- Program effectiveness and evaluation.

- Must be a written program.

- OSHA's Template - Appendix D

- Must be administered by a trained program administrator.

All healthcare facilities, regardless of size and/or type of care given, may find the following resources helpful in creating a Respiratory Protection Plan.

OSHA resources

- OSHA/CDC/NIOSH Hospital respiratory protection program toolkit (this is applicable to all health care settings).

- Appendix C is an evaluation checklist.

- Appendix D is a program template.

- OSHA: Small Entity Compliance Guide for Respiratory Protection Standard.

- OSHA: Respiratory protection training videos

CDPHE resources of the OSHA respiratory protection standard

- CDPHE RPP Checklist

- CDPHE RPP Toolkit

- CDPHE RPP Development webinar recording

- CDPHE RPP Development slide presentation

- CDPHE RPP Template Basics - Additional information on what each section of the written program should include.

Additional resources

- OSHA Colorado offices

- CSU Occupational Health and Safety Consultation - Free occupational health and safety consultation services.

- National Jewish Health: Respiratory Protection Program services - Fee for service resources.

- AAOHN RPP Training - Free training for program administrators.